In this third article covering the MAN Support Vehicle In UK Service we look at the basic technology of the more numerous MAN HX range variants, writes Carl Schulze.

~

The UK Forces Support Vehicle (SV) fleet consists of both MAN HX chassis range Medium Mobility (or MM) trucks and MAN SX chassis range Improved Medium Mobility (or IMM) trucks.

MAN HX Truck Technology: The Support Vehicle Cargo Light (or SVCL) 6 Tonne 4×4 model, the Support Vehicle Cargo Medium (or SVCM) 9 Tonne 6×6 Medium Mobility model, the Support Vehicle Cargo Heavy (or SVCH) 15 Tonne 8×8 model, and the Support Vehicle Unit Support Tanker (SV UST) 6×6 Medium Mobility model are all members of the HX high-mobility truck range of tactical military trucks specially designed by MAN. They feature a low-torsion ladder chassis frame utilising riveted and bolted cross-members as well as a steel front bumper. Attached to the sides of the frame are robust carriers that hold the fuel tank, brake system pressure tanks, battery box and storage boxes for vehicle-related equipment. The SVCL features a 300-litre aluminium fuel tank, while the other HX variants are fitted with a 400-litre fuel tank.

The modular forward control cab features built-in rollover protection, an 800mm-diameter roof hatch and a right-hand-drive layout. The cab can tilt hydraulically to allow access to the engine compartment for maintenance and repair. A front flap is available to simplify daily routine maintenance work. The removable top of the cab holds an air-conditioning unit.

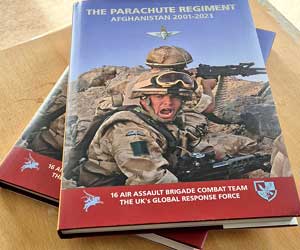

The cab of SV trucks can be tilted hydraulically to grant access to the engine compartment for repair and maintenance – this is a SVCL 6 Tonne 4×4 MAN with Winch [© Andy Brend]

Inside the cab, two ergonomic, high-comfort seats with adjustable and lockable air suspension are provided. A third, central, seat with foldable backrest is positioned below the roof hatch. The cab is prepared for fitting the Installation Kit – Electrical Equipment, which allows a Bowman communication equipment suite to be installed. All vehicles are fitted with an electric 24V boiling vessel (or BV) manufactured by Electrothermal Engineering Limited.

The System Carrier Unit mounted behind the cab incorporates the entire cooling system for the engine, air intake system, exhaust system, components of the brake system, major parts of the vehicle’s hydraulic system and the spare-wheel carrier with hoist. All vehicles, except for the first 161 delivered to establish an initial training capability, are prepared for, but are not fitted with, a Modular Armour Kit and a Riotous Protection Kit (more about this in Pt5).

The SVCL variants are powered by a MAN D0836 LFG 50 Euro 4 common rail, water-cooled, 6-cylinder diesel engine with direct fuel injection that develops 326hp at 1,900rpm. All other HX range variants of the SV fleet are powered by a MAN D2066 LF34 Euro 4 common rail, water-cooled, 6-cylinder diesel engine with direct fuel injection that develops 440hp at 1,900rpm. The engine of the SVCL is connected via an automatic single dry plate clutch to a ZF AS 1210 TipMatic transmission with manual mode, that features twelve forward and two reverse gears. All other HX variants feature a ZF AS 2301 TipMatic. All vehicles have a two-speed transfer case with disengageable front-axle drive and neutral position. All axles are of the double-reduction planetary drive gear type and feature mechanical differential locks. They are fitted with 10.00W-20 disc rims and Continental 14.00 R20 HCS tubeless radial tyres.

This similar SV Cargo Heavy, towing a trailer, was operationally deployed to Estonia with Royal Engineers on Op CABRIT in 2017 [©BM]

The suspension of the HX range features long, wear-free, rubber-mounted parabolic leaf springs and large hydraulic telescopic shock absorbers on the front axle, and trapezoidal spring units with stabilisers on the rear axles. In the case of 4×4 and 6×6 vehicles, only the front axle is steered, while on 8×8 vehicles the first two axles are steered. The steering system is hydraulically assisted and features recirculating ball steering gear manufactured by the German company ZF Lenksysteme GmbH.

Trucks are fitted with a load-sensitive, dual-circuit air brake with automatic slack adjustment. S-cam drum brakes are employed on all wheel stations. The MAN BrakeMatic electronic brake system regulates the braking power of each wheel individually and incorporates an ABS. The vehicles are also fitted with an exhaust valve brake. The parking brake is of the mechanical type, and acts on the rear wheels.

Except for the UST MM model, all HX range vehicles are fitted with a trailer hitch and connectors for supply and control circuits of trailer air-actuated brakes, and a socket for power supply to the trailer’s electrical system. The electrical system of the trucks works on 24V, and includes a 28.5V/120A three-phase alternator and two 12V/100Ah batteries. Vehicle electronics include a fully integrated Controller Area Network (CAN) vetronic structure. A vehicle management computer controls driveline and running-gear functions, while a central on-board computer controls instrumentation and fulfils diagnostic purposes. A heads-up fault code display is linked to the J1939 CAN bus. A MAN health and usage monitoring system records operating data to benefit condition-based maintenance.

For self-recovery purposes, a number of SVCL, SVCM MM and SVCH variants are fitted with a winch; types fitted being the Rotzler HZ 051 (96m-long rope, 12mm diameter and 50kN pulling force) and Rotzler HZ 090 (67m-long rope, 16mm diameter and 100kN pulling force). The rollers sit behind the front bumper just inboard of the left headlight cluster; see tilted cab photo above.

In Part 4 of 5 we plan to look at the technology of the higher mobility MAN SX chassis range variants, and then at the MAN Support Vehicle cargo bodies and CALM (Crane Attachment Lorry Mounted) versions.

[images © Carl Schulze or Bob Morrison unless noted otherwise]

- MAN Support Vehicle In UK Service ~ Pt1

- MAN Support Vehicle In UK Service ~ Pt2

- MAN Support Vehicle In UK Service ~ Pt3

- MAN Support Vehicle In UK Service ~ Pt4

- MAN Support Vehicle In UK Service ~ Pt5 – coming soon

Pingback : MAN Support Vehicle In UK Service ~ Pt2 - Joint Forces News

Pingback : MAN Support Vehicle In UK Service ~ Pt1 - Joint Forces News

Pingback : MAN Support Vehicle In UK Service ~ Pt4 - Joint Forces News