The German tank manufacturer FFG from Flensburg will present a new innovative recovery module for the BOXER at this year‘s DSEI 2019 in London.

~

Press Release, Flensburg, 27 August 2019: Whereas various mission modules already exist to configure BOXER as ambulance, battle damage repair, cargo, command post, engineer group, infantry fighting or troop carrier vehicle, a potent recovery module was missing. FFG identified this capability gap in the BOXER fleet and developed an innovative recovery module since starting the project in October 2017.

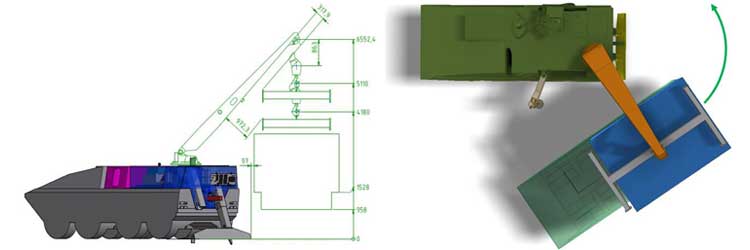

The recovery module is armoured and weighs approx. 13 tons. The pivoting crane boom is 5.3m long and can lift up to 20 tons and is positioned at the rear of the recovery module. It can perform all common maintenance and recovery tasks such as changing weapon turrets, engines or mission modules – including its own – or e.g. the lifting of vehicles for wheel changes. The second essential component is a modern capstan winch with a 60 metre Kevlar rope and a pulling force of 20t for recovery and self-recovery. The recovery module features comprehensive additional capabilities e.g. cutting and welding equipment, pneumatic power tools and more. For self-defence the system can be equipped with a remote controlled weapon station.

To ensure a safe state of the MRAV BOXER when operating the new mission module deploys its own stabilising support legs and a rear anchor. The hydraulically expendable stabilisers secure the module during crane and winch operations and relieve the driving module of the associated stress at the same time. The recovery module is connected to the driving module through standard BOXER mechanical interfaces and for operation only requires on-board electricity to charge its own battery suite which supplies the recovery module with power and drives the hydraulic system. Due to this semi-autonomous electro-hydraulic design the recovery module can operate, including heavy recovery tasks, even when the chassis’ main engine is switched off during silent watch operations and may temporarily run completely independent from the drive platform.

The module provides space for two crew members, Commander and Gunner. Control and monitoring of all systems is conducted centrally via touchscreen displays and proprietary FFG software. Manual control of the hydraulics in emergency mode remains possible. General on-board equipment such as the CBRN protection system, HVAC etc. are, wherever possible, integrated with existing BOXER components to ensure maximum logistic commonality with the other mission modules. With FFG’s recovery module, BOXER user nations can effectively close a major capability gap within fleets, since it enables BOXER to carry out all those maintenance and recovery tasks that to date require heavy tracked recovery vehicles or specialist civilian vehicles.

Interested visitors to the DSEI 2019 are invited to discover the BOXER Recovery Module and to receive comprehensive information on all products and services provided by the German vehicle manufacturers.

Pingback : DSEI 19 ~ BOXER Recovery World Première - Joint Forces News