Northrop Grumman supports successful US Space Force-12 (USSF-12) mission onboard a United Launch Alliance Atlas V rocket.

~

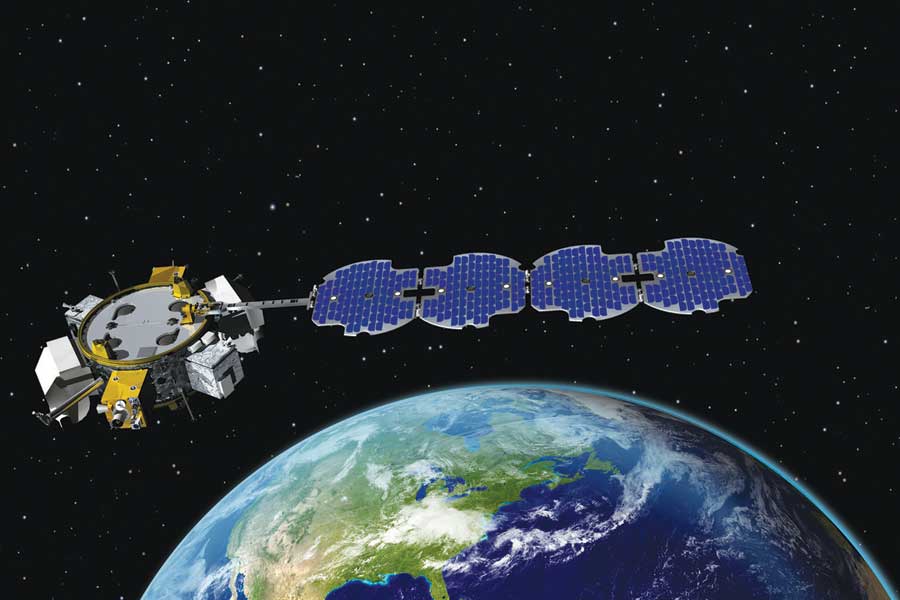

Press Release, Dulles, 02 July 2022: Northrop Grumman Corporation played a vital role in the successful launch and deployment of the US Space Force (USSF)-12 mission which launched last night from Cape Canaveral Space Force Station. As part of this mission, a Northrop Grumman-built ESPAStar satellite and a Wide Field of View testbed missile detection satellite launched on a United Launch Alliance (ULA) Atlas V rocket, powered by Northrop Grumman-provided solid rocket boosters and other critical components.

The ESPAStar platform supports a wide range of missions by utilising the ESPA standard. ESPAStar is equipped with multiple payload ports that can accommodate hosted and free-flying payloads.

“ESPAStar provides rapid access to space,” said Troy Brashear, vice president, national security systems, Northrop Grumman. “As the ESPAStar mission owner, we combined critical technology into a single cohesive mission, including hardware integration and test, ground software, command and control development and integration, mission execution planning, and on-orbit operations.”

Four of the company’s 63-inch-diameter Graphite Epoxy Motors (GEM 63) solid rocket boosters provided approximately 1.5 million pounds of thrust at launch to help lift the rocket and payload from the pad. Earlier this month, the company finalised a contract for its GEM solid rocket boosters to fly on ULA’s next-generation Vulcan rocket, one of the largest commercial solid rocket motor contracts in history.

Northrop Grumman also provided numerous subsystems for the ESPAStar bus, including the solar arrays, propellant tanks, satellite and star tracker structures.

Using advanced fibre placement manufacturing and automated inspection techniques, Northrop Grumman produced the composite first-stage heat shield, the Centaur Interstage Adapter that houses the second-stage engine, and the broadtail that adapts from the core vehicle to the five-metre diameter fairing. The company also manufactured hydrasine propellant tanks, which feed the Centaur Upper Stage reaction control system to provide guidance and control.

~