Curious readers have asked if we can provide any more information on the Land Rover Defender 110 All-Terrain Electric Research Vehicle, writes Bob Morrison.

~

Images of the Defender 110 A-TERV which we published in a footnote to the recent announcement of a contract award to “enable the British Army to extend the life of its Land Rovers as diesel becomes obsolete” (see Project LURCHER ~ Babcock Awarded Support Contract) piqued reader curiosity and prompted me to delve into my photo archives.

At the 2013 Geneva Motor Show, which ran from 7th to 17th March, Land Rover previewed the Defender 110 All-Terrain Electric Research Vehicle (A-TERV or ATERV) rolling laboratory. Seven of these vehicles were built to test technologies that might one day be introduced in future Land Rover models but there were no plans to develop these Defenders into production models, not least because the original Defender was scheduled to be replaced a couple of years later. At least three of these testbed Land Rovers appeared at the Land Rover 65 event at the start of May 2013 and I was lucky enough to have the chance to drive three of the prototypes around the Packington Estate to assess their performance for myself.

In May 2013 the A-TERV testbeds were powered by a 94bhp (70kW) electric motor that developed 330Nm of torque, compared with the 122bhp and 360Nm of the 2198cc Ford Duratorq diesel engine of the time. The electric motor drew on a 300-Volt, 27kWh lithium-ion battery which gave a range in excess of 50 miles and in low speed use the battery lasted eight hours before needing recharging; a 7kW fast charger took four hours to rebuild full capacity.

With the electric motor delivering maximum torque from starting the A-TERV did not require the standard Land Rover gearbox and the transmission comprised a single speed 2.7:1 reduction gearbox linked to the standard Defender permanent 4-wheel drive system and differential lock. A specially modified version of the Land Rover Terrain Response system was also incorporated.

The biggest disadvantage of these test vehicles was the comparatively low amount of battery power available at the time, and the length of time needed to recharge. However back in 2013 Land Rover’s Roger Crathorne assured me that technology in this field was advancing so quickly that he fully expected to see electric vehicles with similar range as petrol or diesel equivalents plus ultra-fast charging times well within the decade, and he has been proved correct. By the end of July 2013 testbed OE62VUM, the Truck Cab featured here, had been further modified and dispatched to the Eden Project in Cornwall for trials in the real world (see original Land Rover press release below).

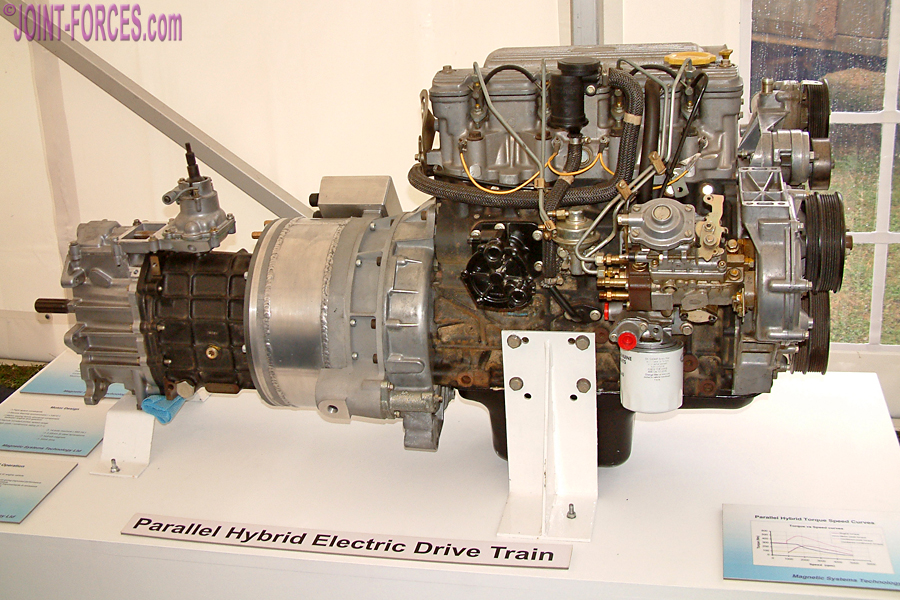

Incidentally, almost a decade before the Defender A-TERV was sent off to Cornwall for trials Rotherham-based Magnetic Systems Technology (MAGTEC) presented a Hybrid Electric Drive Train at Defence Vehicle Dynamics 2013 and this company has been heavily involved in the British Army’s hybrid propulsion JACKAL, FOXHOUND and MAN SV project.

[above images © Bob Morrison]

~ $ ~ $ ~

Land Rover’s Innovative Electric Defender Research Project Begins Real-World Trials At Eden Project

Press Release, Whitley, 31 July 2013: The first Electric Defender has started work at the Eden Project near St Austell in Cornwall in an inaugural real world trial of its capabilities. Unveiled at this year’s Geneva Motor Show, the Land Rover Electric Defender is a pioneering research project into the electrification of an all-terrain vehicle.

The project forms part of Land Rover’s overall sustainability objectives which have included the move to aluminium platforms in the latest all-new Range Rover and Range Rover Sport as well as the forthcoming Range Rover hybrid products. The innovative 4×4 is a rolling laboratory to develop new ideas, and investigate electrification in a real-world environment. A fleet of six vehicles will be placed with organisations where their performance can be assessed.

The Defender 110 Pick Up badged ‘All terrain Electric Research Vehicle’ effortlessly tows the four-carriage 12 tonne road train carrying up to 60 passengers on a 6 per cent incline to and from the iconic hexagonal-panelled domes. The vehicle has been designed to perform its duties throughout each day before being recharged over night for the approximate cost of £2.00.

The Electric Defender has all the qualities and performance which have become associated with the Land Rover brand during the past 65 years. It has full all-terrain capability, permanent 4WD and a top speed of 70mph. However, it has been engineered in-house by Land Rover to test out the latest sustainable technologies. The vehicle’s Hill Descent Control is linked to a regenerative braking function, and overall up to 80 per cent of the car’s kinetic energy can be recovered. During each downhill trip at the Eden Project up to 30kW will be fed back into the batteries. Land Rover’s acclaimed Terrain Response system has been adapted for electric drive, offering a 50-mile range with a reserve of a further 12.5 miles. The result is a zero tailpipe emissions vehicle like no other; eight hours of low-speed off-road use is achievable, and it takes 10 hours for the advanced lithium-ion batteries to be fully charged. ‘Fast-charge’ technology reducing that to just fours is also possible.

Jeremy Greenwood, Principal Engineer on the Electric Defender project, said the car was ideal for the sensitive ecology of the Eden Project. In addition, the repetitive nature of the work will provide excellent data for future electric vehicles. “The car has been modified so it now includes a second battery,” Jeremy explained. “That will allow it to work a full day at the Eden Project, but also improves weight distribution and stability. In addition, we’ve linked the land-train’s air brakes to the foot pedal of the Land Rover, enhancing safety.”

Gus Grand, Climate Change Lead at the Eden Project, said: “We’re very pleased to be working with Land Rover on this exciting project. It will be a great talking point for our visitors and proves that electric vehicles can be every bit as tough and rugged as their fossil fuel counterparts, while being much quieter, cheaper to run and with zero emissions at the point of use.

~