In this fourth part of the GTK Boxer Story Carl Schulze talks numbers and discusses the vehicle’s technology.

Original planned production was 272 GTK Boxer MRAV for the German Bundeswehr and 200 for the Royal Netherlands Armed Forces; subsequently Germany increased its requirements by 131 at the end of 2015 but we are limiting the scope of this set of articles to the original orders. Delivery of the last German vehicle from the first batch was scheduled for 2016, with the second batch planned to be complete by 2020, and the last Dutch vehicle should be in service this year. Australia, Lithuania and Slovenia have now also selected Boxer and this April it was confirmed that the UK had rejoined the programme; in-service date for British Boxers is, as announced on 24th May 2018, projected for 2023.

A Dutch Genie Voertuig (engineer section vehicle) photographed in Estonia during KEVADTORM 17 [© Bob Morrison]

The Bundeswehr originally ordered a total of 125 GTK Boxer A0/A1 Gruppen transport fahrzeug or wheeled APC versions, 65 of the A0/A1 Führungs fahrzeug or command post vehicle variant, 72 of the A0/A1 schwere geschützte Sanitäts fahrzeug or heavy ambulance, and ten of GTK Boxer Fahrschul fahrzeug or driver training vehicles. Eventually all vehicles will be modified from the earlier A0 standard to A1 standard.

The Netherlands ordered their 200 GTK Boxer MRAVs in the following six different variants: 60 Boxer Commando Voertuig or command post vehicles; 52 Boxer Gewonden Transport Voertuig or heavy ambulances; 41 Genie Voertuig or engineer section vehicles; 12 Boxer Battle Damage Repair Vehicles; 27 Boxer Cargo Voertuig or cargo carriers; and eight Rijles Voertuig or driver training vehicles.

The Boxer MRAV has been designed for an in-service lifetime of some 30 years. According to information provided by the OCCAR Boxer Programme Division, development and production of the originally order GTK Boxer MRAV amounted to 1.429 billion Euros.

Technology

Each soldier in the rear fighting compartment has an individual shock-absorbing seat that features an adjustable back and head rest plus four-point safety harness with integrated air bags in the shoulder straps [© CS]

Right from the beginning, during the development of the Boxer MRAV great attention was paid to addressing the requirements of modularity, high level of armour protection, mobility and high payload. As a result of this the MRAV features a modular design with each vehicle consisting of an 8×8 drive module and a mission module. According to information provided by the ARTEC GmbH, it is possible to exchange mission modules from one drive module to another within 30 minutes.

The Boxer, due to the use of state-of-the-art technology, offers a high degree of protection from: small arms fire, heavy machinegun fire, and medium calibre automatic cannon fire; bomblets and artillery shell fragments; all types of anti-personnel and anti-tanks mines, even in case of under belly detonations; and IEDs, even in case of heavy blasts, including also mines and IEDs that employ explosive formed penetrator (EFP) technology. The basic shell of the vehicle is made of high-hardness steel onto which the Advanced Modular Armour Protection (AMAP) composite armour, which incorporates a special ceramic mix, is installed on shock absorbing mounts.

The gunner is seated behind the driver on the right side, in the centre of the hull – in front of him the control panel for the FLW 200 RCWS is situated [© CS]

The modular design of a multi-layer floor concept and the safety cell of the vehicle minimise the ‘catastrophic kill’ risk in the case of an underbelly mine and IED blast. The roof armour of the vehicle offers protection from top attacks. The modular design of the armour package also allows for the integration of new armour technology, should this become available, and also the installation of add-on armour packages. To reduce the likelihood of a hit by guided weapon systems the vehicle has been designed taking in account the rules of stealth principles, reducing its acoustic, infrared and radar signature to a possible minimum.

Driving Module

The driver’s compartment is situated to the front right – the steering wheel can be adjusted in height and to the right is situated the automatic transmission gear selector [© CS]

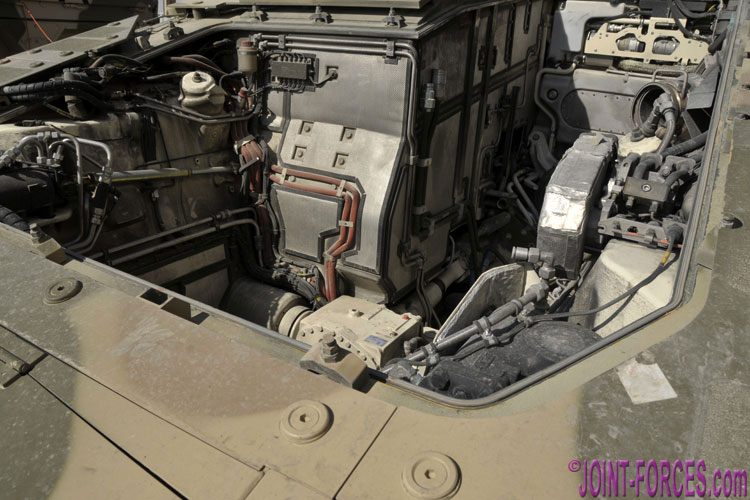

The driving module is completely independent and identical for both German and Dutch variants. Its chassis and hull house, among other components, the driver’s compartment, the power pack compartment, the drive train, the brake system, the steering system and the eight independent wheel station type suspension units, including coil springs and shock absorbers. While the driver is seated to the front right in the hull the power pack compartment is situated at the front left.

All current GTK Boxer MRAV variants are powered by a MTU 8V 199 TE20 8-cylinder V turbocharged, inter-cooled, EURO III compliant, diesel engine that develops 720hp and allows the vehicle to reach a top speed of 103km/h. Together with the RRW3001 angular gearbox, the seven speed Allison HD4800SP automatic transmission, the cooling system and other components the engine forms the power pack. This pack can be exchanged in about 20 minutes.

The drive train of the vehicle also includes two inter-axle differentials and four axle differentials. The wheels are fitted with Michelin 415/80 R 685TR XML TL160 tyres that include Hutchinson run-flat inserts, which allow to drive the vehicle another 30km at a speed of up to 50km/hr even when several or all tyres are damaged. The central tire inflation system (CTIS) benefits the cross country mobility of the vehicle and can be set on prescribed settings.

The GTK Boxer features an independent wheel station type suspension consisting of twin coil spring and shock absorber units [© CS]

The steering system, which has a steering wheel rather than levers, is of the power assisted type and works on the two front axles. The vehicle is fitted with a steering brake that allows stopping of all four wheels on one side and by doing so skid-steering is possible, which drastically reduces the vehicles turning radius. The vehicle brake system is of the hydraulic dual-circuit disc brake type and integrates ABS.

Also situated in the driving module are the battery box of the 24-Volt electrical system, the three fuel tanks containing 280 and 238 litres plus a back-up 44 litres, the air conditioning system, the heating system and the fire detection and extinguishing system. The electrical system and all vehicle functions are monitored by a CAN bus system that features two redundant ring structures integrated with the driving and mission module.

To be continued…..

The power pack compartment is situated to the front and left of the driver’s compartment – here the engine has been removed for maintenance purposes [© CS]

Report and images © Carl Schulze unless noted.

See also:-

Pingback : Artec Confirms More Than 500 Boxers Ordered By UK - Joint Forces News

Pingback : British Army MIV ~ Boxer Order Finally Placed - Joint Forces News

Pingback : GTK Boxer Multi-Role Armoured Vehicle ~ Part 1 | Joint Forces News

Pingback : UK BOXER MIV at Millbrook Proving Ground | Joint Forces News